-

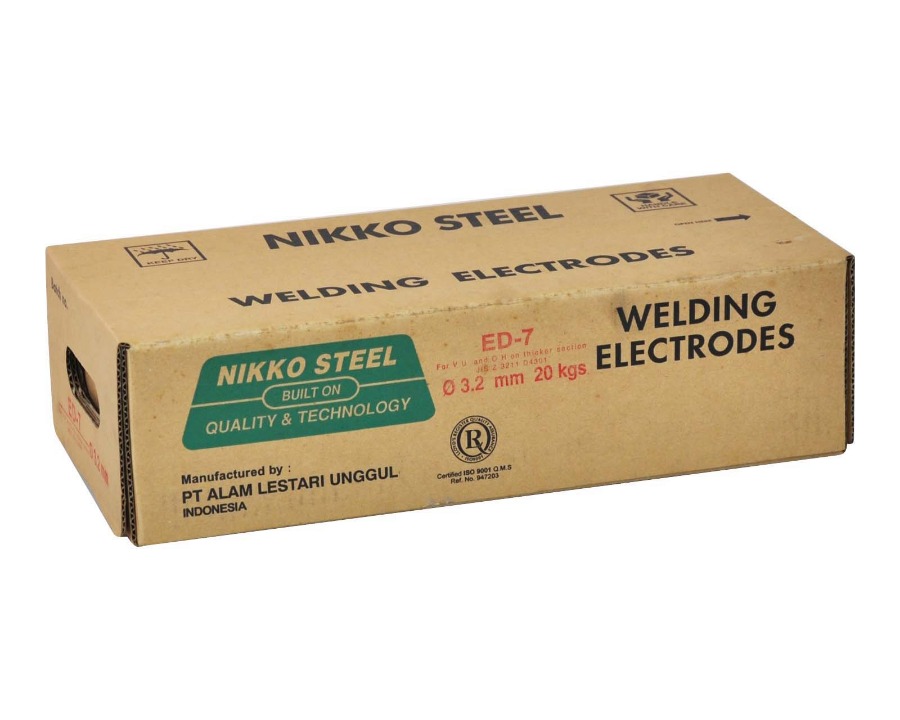

ED-7

CLASSIFICATION

JIS Z 3211 D4301

PRODUCT DESCRIPTION

The combination of illmenite and amphoteric minerals are balanced to produce a highly viscous slag ideal for vertical up techniques when a heavy weld deposit is needed and also overhead welding. The flux containing alloying and deoxidising ferro alloys are extruded onto a mild steel core wire using a blend of potassium rich silicates that ensures both coating strength and a coating resistant to subsequent moisture absorption.

WELDING FEATURES OF THE ELECTRODE

Arc stability is excellent both AC and DC. Weld seams are smooth and evenly rippled and fillet welds are slightly convex. Slag detachability is also very good. The physical soundness of the welds are excellent with reference to x-ray quality as its resistance to solidification cracking on relatively thick steel sections. Metal recovery is some 95% with respect to weight of core wire

APPLICATIONS AND MATERIALS TO BE WELDED

All positional welding of structural steels, particularly using vertical up and overhead techniques for the following and related steel specifications: Mild and medium carbon-manganese steels up to 15 mm thick (for several circumstances can be used up to 25 mm thickness) with a UTS of 500 N/mm2 max. Typical grades : BS 1449 plate and sheet, BS 4360 grades 43A and 43C, Lloyds A & D ship steel BS 4360 grade 50B Lloyds grades AH and DH, BS 3059 and BS 3601 grade 320-410 API 5L A-B and X42

WELDING AMPERAGE AC and DC

OTHER DATA

Electrodes that have become damp should be re-dried at 110oC for 1 hour