For Welding Low Carbon Austenitic Stainless Steels Containing A Nominal 23Cr-12Ni Used For Dissimilar Welds Between Stainless And C-Mn Steels

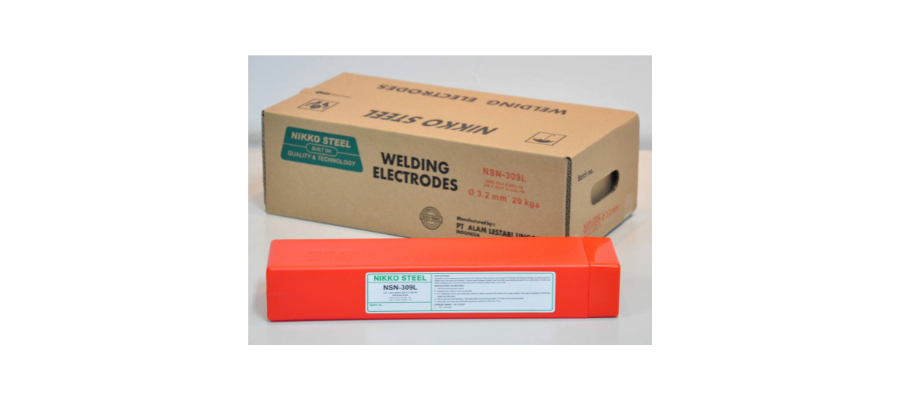

NSN-309L

CLASSIFICATION

AWS A5.4 E309L-16 | EN ISO 3581-A E 23 12 L R | JIS Z 3221 D309L-16

PRODUCT DESCRIPTION

A metallurgically advanced rutile based flux formulated with balanced additions of chemically basic, amphoteric and acid minerals, together with small alloy additions to compensate for arc losses. The flux is concentrically extruded onto a fully alloyed core wire and bound by a blend of silicates that assures both coating strength and resistance to subsequent moisture absorption

WELDING FEATURES OF THE ELECTRODE

This unique flux formulation ensures excellent arc stability, ease of initial arc strike and re-strike minimal spatter on AC and virtually none on DC+. The resultant weld seams are smooth, evenly rippled and free from undercut while slag detachability is excellent. Metal recovery is some 103% with respect to core wire weight

APPLICATIONS AND MATERIALS TO BE WELDED

Applications for the electrode are to be found in the Chemical, Petro-Chemical and Cryogenic Processing and Storage Industries as well as the Food, Brewery and Pharmaceutical Industries. Transition welds between stainless steel and ferritic steel welding clad plate or as a buffer layer on ferritic steel before completing with a more conventional low carbon austenitic stainless steel, such as 304L.

WELDING AMPERAGE AC and DC

OTHER DATA

Electrodes that have become damp should be re-dried at 150oC for 1 hour